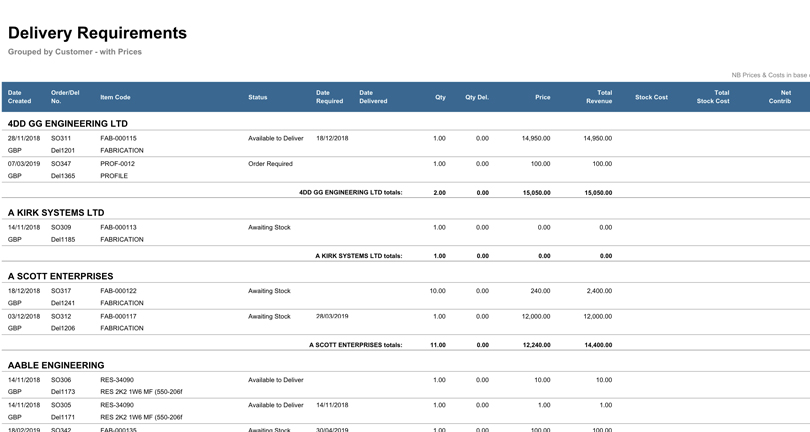

E-Max gives you full visibility of all jobs throughout the manufacturing process. As E-Max is an end-to-end system, it takes each job from initial enquiry through to final invoice and accounts.

E-Max gives you full visibility of all jobs throughout the manufacturing process. As E-Max is an end-to-end system, it takes each job from initial enquiry through to final invoice and accounts.

For companies trying to achieve or maintain ISO 9000 or other accreditations, E-Max’s software for manufacturers has built in processes to make continuous improvement easy to manage. Also included is a comprehensive quality system, with full traceability, testing and non-conformance recording, giving your company the opportunity to enter new regulated markets or meet new contractual agreements.

Get rid of multiple spreadsheets and put all your information in one place for better analysis. Use this improved knowledge to become more competitive and win more contracts, for example, by using historical data to see how low prices can be taken but still remain profitable.

Find out how it will benefit your business.

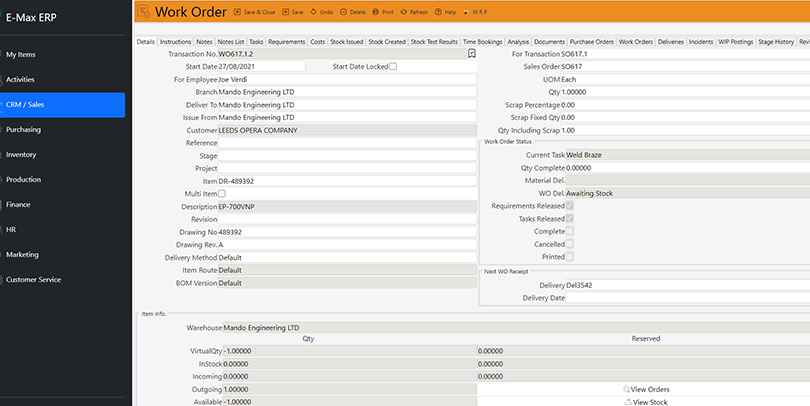

With E-Max ERP’s BOM, you can create a central resource for every job, with all raw materials, items, sub-assemblies, etc, required to produce the finished product. Save time by copying and configuring existing BOMs for new jobs.

Easily create multiple routes for every job, then store, access and use for future jobs. With E-Max ERP’s routing you can use set up times, run times, cycle times, and specify processes and resources for each individual task or operation. Existing routes can be copied and altered for similar jobs.

Bring your BOMs and Routing together to create the works order for the most efficient production process, taking into account available resources and materials.

Reduce downtime and waste by scheduling jobs more efficiently with E-Max’s capacity planner and finite scheduling functionality. Match resource and availability and get jobs out of the door on time.

Thomas Lapsley

Operations Director

Lamond & Murray